We're the first industrial shock absorber supplier to offer an FMU!

Our services are expanding, with digital twins to be integrated into virtual models. This service is complementary to the configuration and calculation software available online, CAD drawings and simulations solutions.

What is a FMU?

These are functional mock-ups or, more commonly, digital models. These units represent the performance of a system or component in a simulation environment.

In this context, for our shock dampers, FMUs represent physical models of the dampers, including their performance:

- hydraulic,

- thermal,

- mechanical.

The precision of this data enables, for example:

- calculate the precise influence of the input temperature on the damping performance of the shock absorber,

- assess its impact on the overall design even before the production phase.

Digital twins

ACE, our historic partner, now offers the possibility to integrate physical models into simulation models for shock dampers, in the form of digital twins.

Digital twins are virtual models that reproduce the physical performance of shock absorbers based on real data. They enable engineers to integrate and simulate dampers in a virtual environment, allowing:

- prototyping

- performance evaluation

- optimisation before production.

This approach offers considerable advantages, particularly when it comes to customising shock absorbers for industrial environments. We can provide you with rapid prototypes in the form of digital twins, reducing development and integration time.

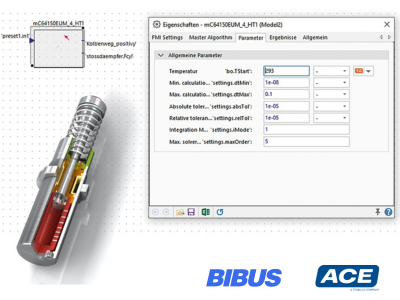

Shock Absorber Digital Twins Simulation Model - Picture provided by ACE Stoßdämpfer GmbH -

Digital Twins Simulation Model 3D Airplane Landing Gear

- Picture provided by ACE Stoßdämpfer GmbH -

Reduce your carbon footprint with digital twins

In addition to their position as an essential component for virtual prototyping and design dimensioning. Digital twins also offer significant benefits in terms of sustainable development.

By reducing the considerable number of physical samples required to complete a project, digital twins help to reduce the carbon footprint and waste generated during the prototyping and testing phases.

With this innovation, we are reaffirming our commitment to providing cutting-edge, environmentally-friendly solutions that respond to the requirements of industry codes.

So save time, money and sustainable resources!

This service is available on demand only!

Contact us and send us your requirements to the following address:

Our experts will take over from there.