Wörner stop and positioning modules

If you want to be able to dampen, stop and/or position your pallet(s), discover our new Wörner stop pallet range and find the right solution for your needs and application.

Damped separators

The function of damped separators is to stop and release a pallet containing fragile and/or brittle parts. Indeed, the stopper places one or more pallets in a defined position and releases them individually for downstream transport, the stopping process is cushioned by a slight deceleration. The pallet is therefore gently braked so that the part reaches the final position without impact, thus, the conveyor is subjected to significantly lower forces.

In addition, proximity switches can be used to identify the upper and lower positions of the stop.

Electric damped

Features

- Smooth deceleration and stopping of the pallet thanks to an integrated damping system

- Impact force reduced by up to 95% compared to unloaded stops

- Precise positioning of the pallet thanks to reliable operation to the end position

- Wide range of applications thanks to a simple and infinitely adjustable damping force

- High efficiency and low operating costs thanks to electromechanical drive

- Low installation costs due to the elimination of the pneumatic system

- Low noise

- Simplified commissioning and maintenance thanks to integrated diagnostic tools (depending on the model)

- Stay in the down position without power supply

11 different models

|

|

New electric stoppers high efficiency

- more than 70% higher efficiency (compared to pneumatic systems)

- integrated sensors

- simple material flow control

- M12x1 plug

6 new models

|

|

Pneumatic damped

Features

- Smooth deceleration and stopping of the pallet thanks to an integrated damping system

- Impact force reduced by up to 95% compared to unloaded stops

- Precise positioning of the pallet thanks to reliable operation to the end position and the absence of opposing forces in the end position.

- Wide range of applications thanks to a simple and infinitely adjustable damping force

7 different models

|

|

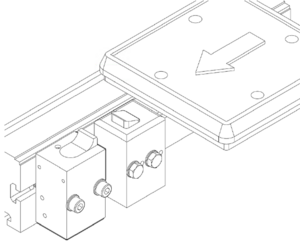

Undamped separators

The function of the undamped separators is to stop the pallet at a specific point and release it. Robust and economical, they can be deployed in scenarios where one or more pallets must be placed in a defined position. In addition, inductive and electronic proximity switches can be used to identify the upper and lower positions of the stop. They also ensure high productivity through short cycle times.

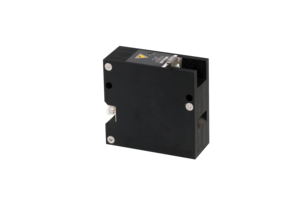

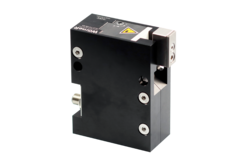

Electric undamped

The stopper places one or more pallets in a defined position and releases them individually for downstream transport. The lowering movement is carried out by an electromechanical drive.

Features

- Compact and robust design

- Easy installation

- Short cycle times

- High efficiency and low operating costs thanks to electromechanical drive

- Low installation costs due to the elimination of the pneumatic system

- Low noise

- Easy commissioning and maintenance thanks to integrated diagnostic tools (depending on the model)

5 different models

- ELU-20

- ELU-30

Small electric separator with magnetic cylinder/Damping effect thanks to elastomer-coated stop plate - DEL0-65

- DEL0-120

- DELW

Pneumatic undamped

The stopper places one or more pallets in a defined position and releases them individually for downstream transport. The lowering movement is pneumatically controlled. Proximity switches can be used to identify the upper and lower positions of the stop.

Features

- Flexible use thanks to a large number of freely configurable variants

- Compatible with different transfer systems

- Compact and robust design

- Any mounting position, easy mounting

- Short cycle times

- Cost-effective

3 different models

- D0-400

- D0-800

- D0-810

To learn more about undamped separators, download the document on the right side.

Anti-bounces stop

Anti-bounces stop ensure that the pallet with its part stops precisely and avoids bounces.

2 differents models :

- DR

- DRP

To learn more about anti-bounces stop, download the document on the right side.

Pneumatic damped for roller systems

Features

- Particularly close construction for direct integration into roller conveyors (without overdrive or increase in roller pitch)

- Smooth deceleration and stopping of the pallet thanks to an integrated damping system

- Precise positioning of the pallet thanks to reliable operation to the end position and the absence of opposing forces in the end position

- Wide range of applications thanks to a simple and infinitely adjustable damping force

3 different models

- DBSR-270

- DBSR-550

- DBSR-1000

To learn more about damped separators, download the document on the right side.

Pneumatic angle dampers

Pneumatic angle dampers are used for stopping with a change of direction or for a change of direction when conveying fragile or brittle parts.

5 different models :

- DBSQ 20-60

- DBSQ-65

- DBSQ-270

- DBSQ-400

- DBSQ-1100

To learn more about angle dampers, download the document on the right side.

Index cylinders

The function of pneumatic indexing cylinders is to lift and position a pallet. Indeed, these cylinders ensure the precise lifting and positioning of the pallet for applications requiring rapid positioning. The part can then be processed on the conveyor without problems and constraints.

2 different models :

- DI-490

- DI-1050

To learn more about the Index cylinders, download the document on the right side.

Contact

________________________________