ACE - Safety Shock Absorber

Safely slowing down damaging forces from moving loads or Emergency braking are united in safety shock absorber products family from ACE. Although the safety shock absorbers, profile dampers and clamping elements differ so much in design, every single ACE component provides the best protection for your machine. They demonstrate their main advantages in emergency stop situations and, based on the protection they provide, are very cost-effective. Furthermore, they can all be easily integrated in the existing construction designs and largely work independent of energy supplies.

As a cheaper alternative to the standard shock absorber, Safety shock absorbers are the tried and tested low cost method of preventing those occasional emergency stops. Designed for occasional use, they primarily serve as reliable, effective protection in emergency stopping for construction designs. The maintenance-free and ready-to-install machine elements are characterised in every respect by the well-known high ACE quality and maximum energy absorption of up to 480,000 Nm/Cycle. This means, in the product family SCS33 up to SCS64 a service life of up to 1,000 full load emergency cycles is achieved. Safety shock absorbers from ACE are available in a large choice with strokes of 23 mm to 1,200 mm, and the arrangement of orifice pattern can be calculated and produced specifically to the customer‘s requirements and depending on the application.

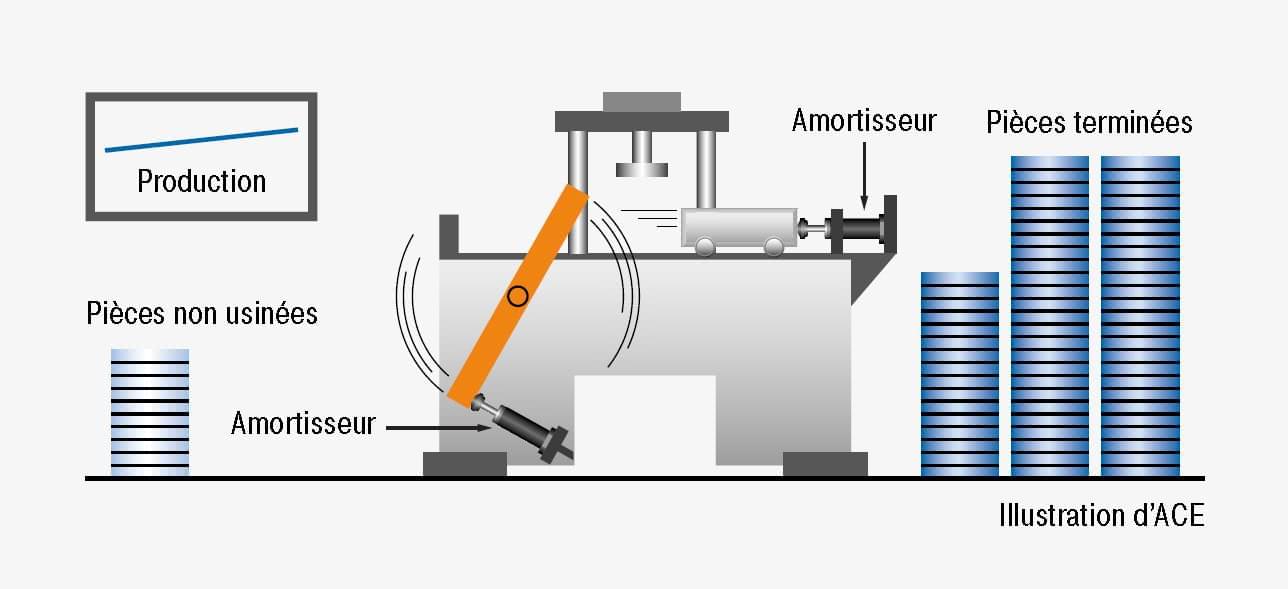

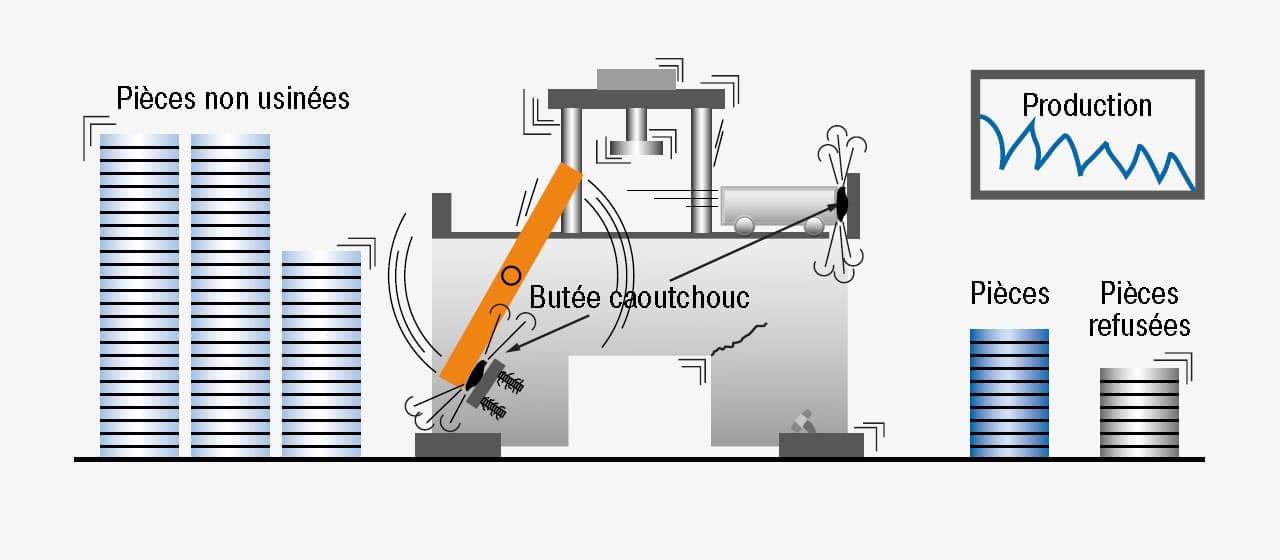

Stopping with Safety Shock Absorbers | Stopping with Rubber Buffers, Springsd, Dashpots or Cylinder Cushions |

|  |

Your advantages using Sefety Shock Absorber | Results using conventional dampers |

The different models of safety shock absorbers

SCS33 à SCS64

Self-Compensating or Optimized Characteristic

Energy capacity 310 Nm/Cycle to 18,000 Nm/Cycle

Stroke 23.1 mm to 150 mm

The ACE Safety shock absorbers SCS33, SCS45 and SCS64 are based on the innovative technology of the successful industrial shock absorbers from the MAGNUM-Series. They are also maintenance-free and ready-to-install. Due to the optimised characteristic curve for the respective application, the energy absorption of these hydraulic machine elements can be increased to more than twice the level of the MAGNUM model of ACE industrial shock absorber per stroke. Users benefit from a service life of up to 1,000 full load emergency cycles with a very good price-performance ratio. Their compact design in sizes M33x1.5 to M64x2 makes them easy to integrate into current applications. These slimline, high-performance safety shock absorbers are only designed for emergency stop situations. They can be used for a number of tasks in gantries and conveyor systems, processing centres or assembly machines.

SDH38 à SDH63

High Rack Damper, Optimized Characteristic

Energy capacity 3,600 Nm/Cycle to 229,100 Nm/Cycle

Stroke 100 mm to 800 mm

The ACE Safety shock absorbers SDH38, SDH50 and SDH63 are used for machine protection in emergency-stop applications. Strokes of up to 1,200 mm are possible with these maintenance-free and ready-to-install dampers. Low support forces result due to the large strokes. The characteristic curve or damping characteristics of all safety shock absorbers from ACE is individually adjusted to the respective application, specific to the customer. The metering orifices for the respective application are specially calculated and produced. These tailor-made machine elements are the ideal protection because they are less expensive than industrial shock absorbers and are effective with up to 1,000 maximum full load emergency cycles possible. Anyone who wants to reliably protect the end positions of rack operating equipment, conveyor and crane systems, heavy duty applications and test benches chooses these safety shock absorbers from ACE.

SDP63 à SDP160

Crane Installations, Optimized Characteristic

Energy capacity 9,100 Nm/Cycle to 582,000 Nm/Cycle

Stroke 50 mm to 1,200 mm

The ACE Safety shock absorbers SDP63, SDP80, SDP100, SDP120 and SDP160 benefit from a safe protection thanks to its internal system seals. Indeed, in case of even dirt or piston rod impairments, risks of component damages are avoid. Compressed gas accumulators allow return forces of up to 100 kN, which can make applications in multiple bridge crane systems safer, for example. The absorber body and the robust, large-sized piston rod bearing are also designed for heavy duty operations. Just like all ACE safety shock absorbers, the characteristic curve or damping characteristics of each individual absorber is individually adjusted to the respective application. Whether its crane systems or machines in heavy duty applications e.g. in the metal industry or in mining, these powerful safety shock absorbers reliably protect construction designs against expensive failure.

Our fittings tips

How to adjust a safety shock absorber correctly ? | How to properly mount two safety shock absorbers in parallel ? |