ACE - Stainless steel shock Absorber

The ACE stainless steel shock absorber are hydraulics components used to decrease a heavy load on automation equipment, especially in aggressive sector like health industry, food, electronics or chemical. Indeed, the materials intended for the composition of this shock absorber were chosen to adapt in a complicated environment while guaranteeing a maximum lifespan. These stainless steel shock absorbers are available to respond at effective masses ranging from 900 g to 42 500 kg and from 20 to 3730 Nm/cycle.

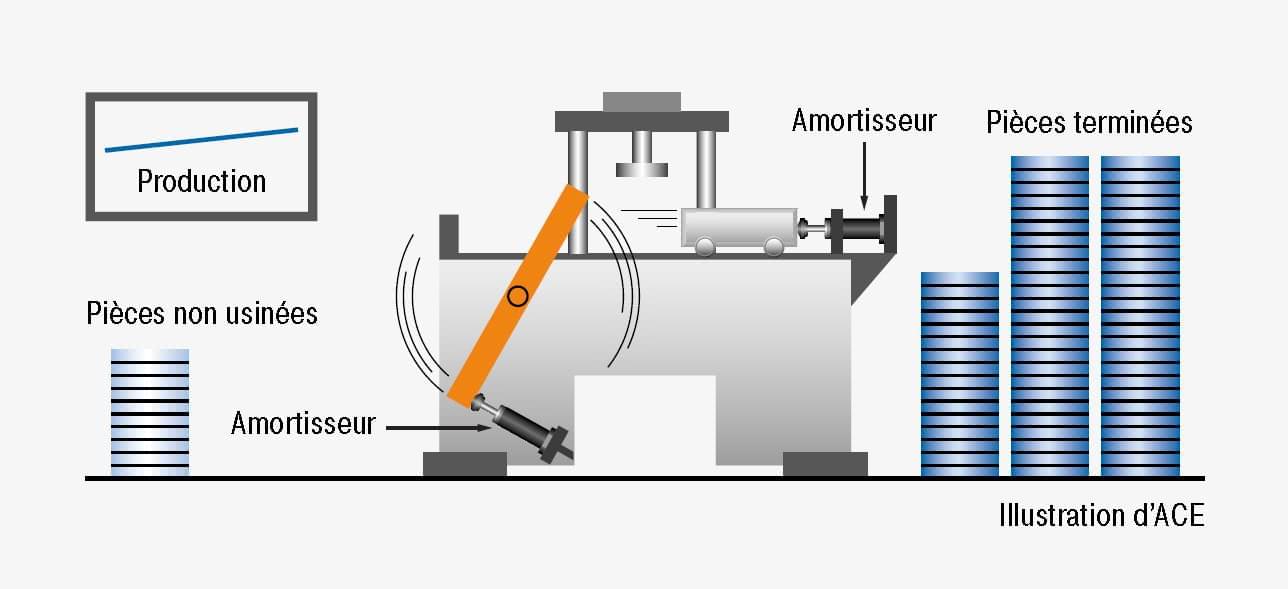

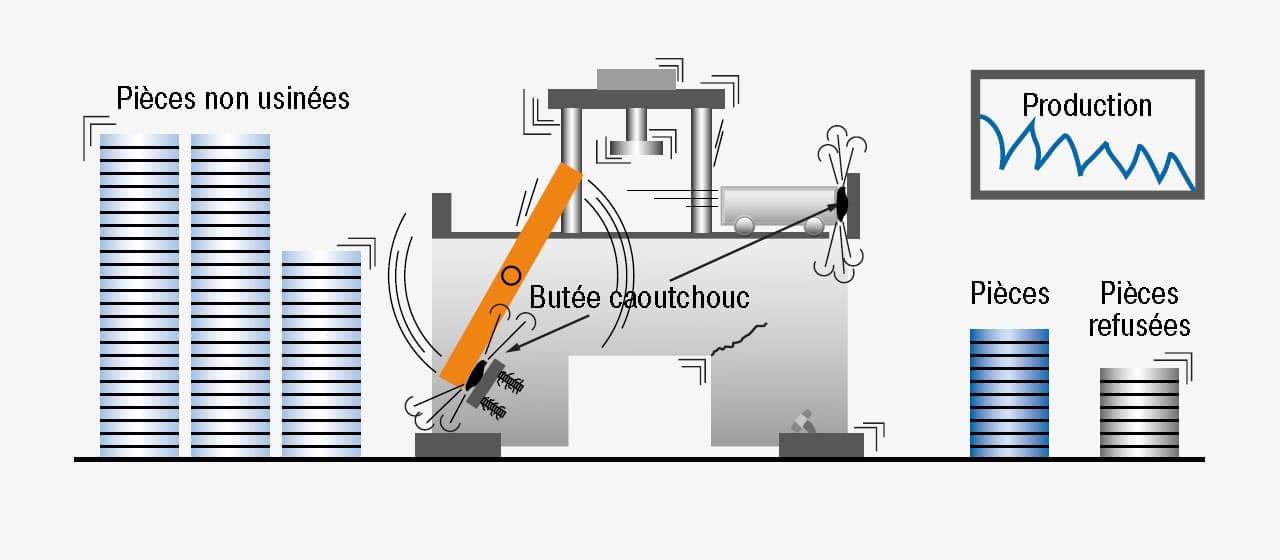

Stopping with Stainless Steel Shock Absorbers | Stopping with Rubber Buffers, Springsd, Dashpots or Cylinder Cushions |

|  |

Your advantages using Stainless Steel Shock Absorber | Results using conventional dampers |

The different models of Stainless Steel Shock Absorbers

MC33-V4A à MC64-V4A

Self-Compensating, stainless Steel

Self-Compensating, stainless Steel

Energy capacity 170 Nm/Cycle to 3,730 Nm/Cycle

Stroke 23.1 mm to 99.4 mm

The ACEself-compensating insdustrial shock absorbers MC33-V4A, MC45-V4A et MC64-V4A are also available with all outer components made from stainless steel, material 1.4404 (except piston rod). They are filled in the factory with special oil, which meets the permit conditions (NSF-H1) for the food industry. Just like the standard product family, the MAGNUM stainless steel models are distinguished by their robust, modern sealing technology, high energy absorption in a compact design, integrated positive stop and a wide damping range. Equipped with a PU head, they are available in thread sizes M33x1.5 to M64x2 with damping strokes up to 100 mm. These self-compensating industrial shock absorbers made of stainless steel from ACE are mainly used in the food, medical, electro and offshore industries, but also in many other markets.

MC150-V4A à MC600-V4A

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology

Energy capacity 20 Nm/Cycle to 136 Nm/Cycle

Stroke 12 mm to 25 mm

The ACE miniature shock absorber MC150V4A, MC225V4A and MC600V4A in stainless steel are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the MC standard units such as the proven ACE rolling diaphragm technology for maximum service life and direct installationin a pressure chamber with up to approx. 7 bar. Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the outer body and a complete range of accessories made of stainless steel (material 1.4404). Miniature shock absorbers made of stainless steel are mainly used in medical and electro-technology, but also in shipbuilding, packaging and chemicals industry and in the food processing. For the latter, they are filled with a special oil in order to fulfil the authorisation conditions (NSF-H1) for this market.

PMCN150-V4A à PMCN600-V4A

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow

Energy capacity 20 Nm/Cycle to 136 Nm/Cycle

Stroke 12 mm to 25 mm

The ACE miniature shock absorbers PMCN150-V4A, PMCN225-V4A and PMCN600-V4A are also available in a stainless steel design. These are particular interest to the food and packaging industries. Their main special feature is the compact, totally sealed bellow between the body and the cap made of TPU (thermoplastic polyurethane). This protection safely encapsulates the ACE rolling diaphragm from the outside environment. Aggressive fluids don‘t stand a chance. The PMCN series is an excellent alternative if the accessory option of the SP type air bleed collar cannot be used due to a lack of compressed air. The PMCN series miniature shock absorbers, produced from stainless steel, are primarily suitable for use in the food industry, but are also wherever an elegant look is important e.g. in shipbuilding.

Our fittings tips

How to adjust a shock absorber correctly ? | How to properly mount two shock absorbers in parallel ? |